UAV Solution for Partial Discharge Inspection

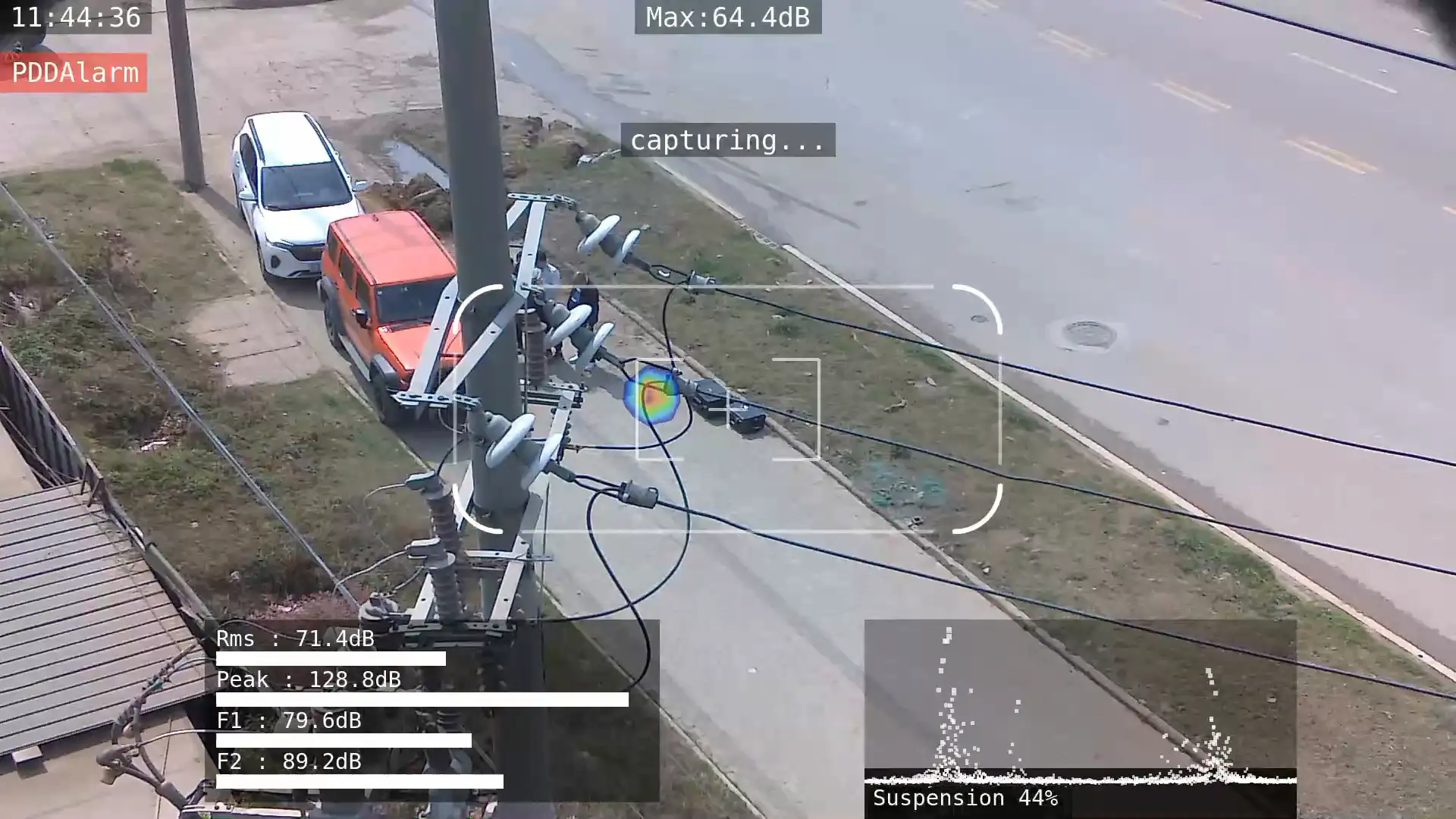

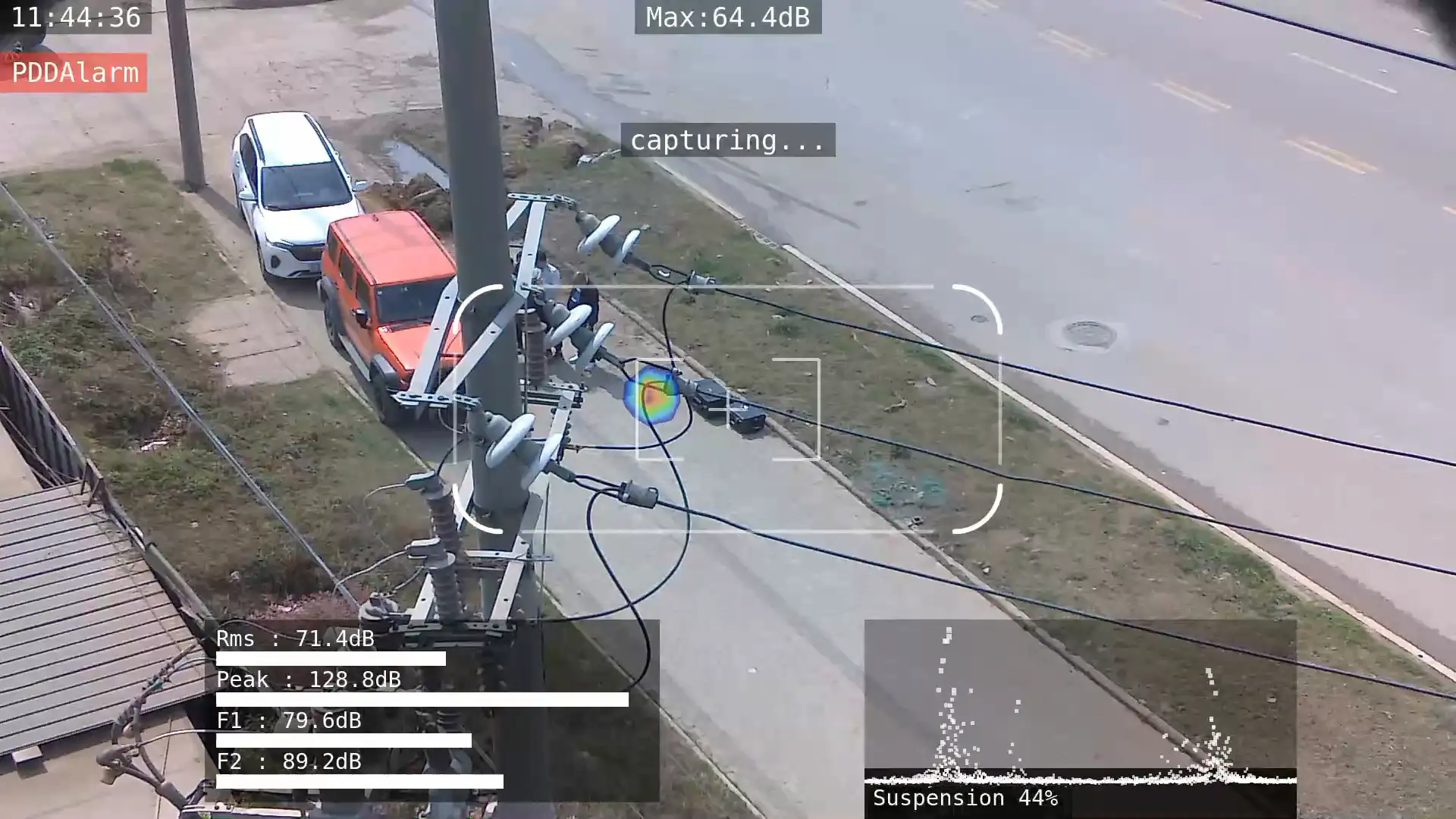

Aerial detection of partial discharge and type recognition

Easily locate partial discharge accurately

Unaffected by variations in light, temperature, and humidity

Detect Partial Discharge (PD) from Miles Away

The acoustic imaging camera installed on the drone can achieve remote detection of partial discharge defects, with an effective operating radius covering 7 kilometers. This innovative non-contact detection technology ensures accurate judgment of the operating status of power equipment and can enter difficult-to-reach work areas to improve the safety and efficiency of operators.

Wide coverage

The operating range of the equipment can cover a radius of 7 kilometers

Guarantee the safety of workers

The homework personnel do not need to be involved in dangerous terrain

Identify the Type of Partial Discharge

The acoustic imaging camera installed on the drone can recognize and identify the type of partial discharge, providing accurate equipment defect diagnosis. By using AI based classification algorithms and PRPD maps, three types of discharges can be distinguished: surface discharge, suspended discharge, and corona discharge.

AI based classification algorithm

Distinguish the characteristics of three types of discharge

PRPD graph technology makes fault diagnosis more intuitive

Distinguishing between faults and noise based on PRPD graph of different partial discharge types

Easy to Reach Remote Areas

The stable operation of the power system is crucial for national energy security, as power lines may be located in hazardous terrain such as mountains, rivers, and lakes, making manual inspections difficult and challenging. With the help of acoustic equipment installed by drones, users can efficiently detect power facilities in hazardous areas.

Fearless of terrain challenges

Relying on drones, the device can function in dangerous terrain

Efficient detection

With the help of drones, equipment can improve the efficience of inspections

Less Cost Compared to UV Cameras & Helicopters

Compared to UV imaging cameras, drone acoustic imaging cameras provide an economical and efficient solution. It is high-resolution imaging technology and provides accurate defect diagnosis at an extremely low cost, offering users a more cost-effective option.

More intuitive imaging

Compared to ultraviolet imaging, acoustic imaging can pinpoint faults more accurately.

Acoustic solutions are more cost-effective

Acoustic solutions are more cost-effective

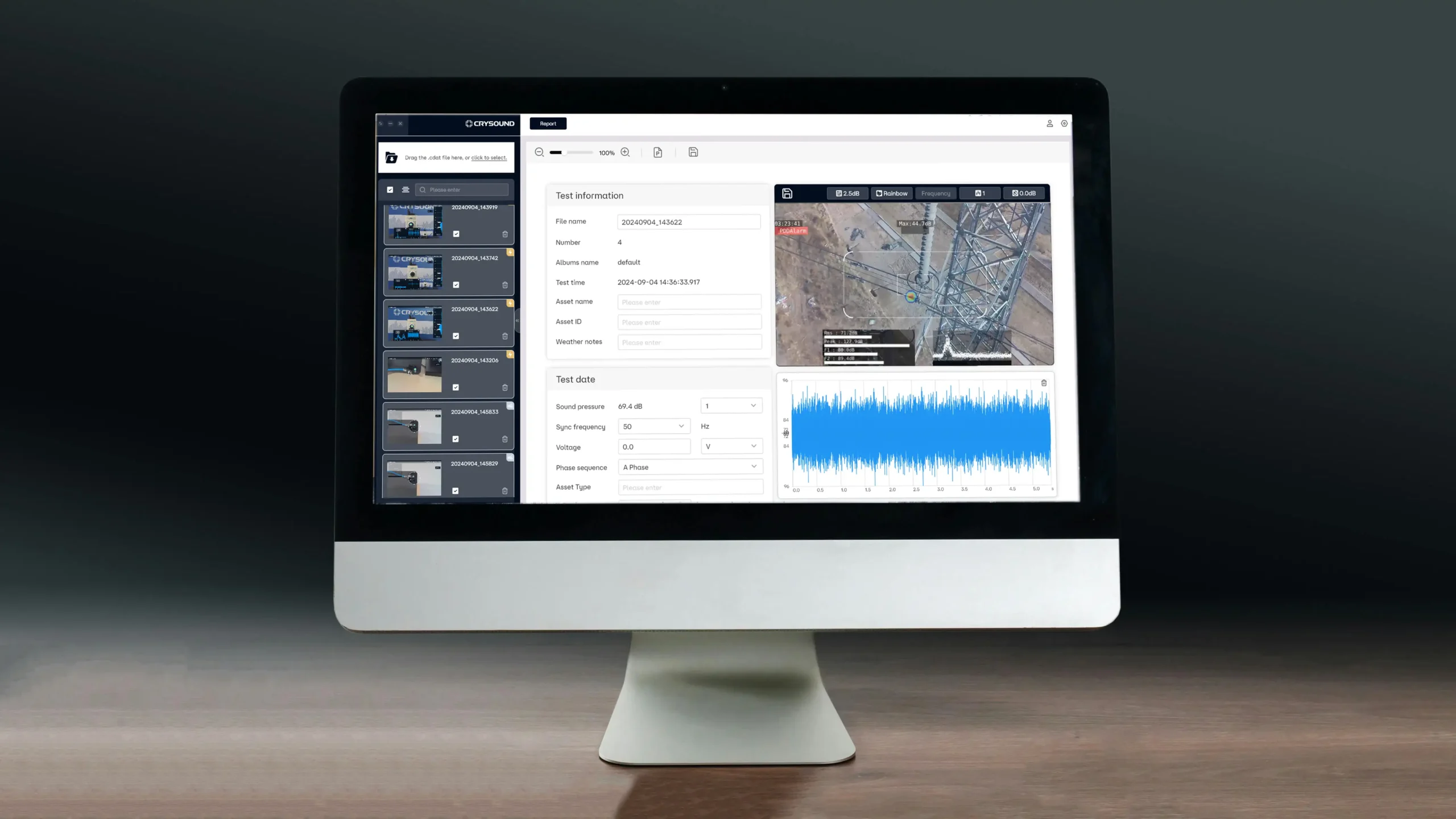

Create & Share Reports

The drone acoustic imaging camera optimizes data collection and reporting, enabling users to quickly generate detailed reports and efficiently convey key information. This simplified process can accelerate the decision-making process, promote better collaborative work, and significantly improve work efficiency and safety.

Key information

The report contains key information about defects, which is more valuable

Report sharing

Simplify workflow and improve collaborative efficiency

Explore More Use Cases

Leveraging Acoustic Imaging for Effective Partial Discharge Detection

Within the intricate tapestry of electrical systems, where the paramount significance of ensuring power distribution safety and reliability cannot be overstated, the swift detection and mitigation of partial discharge (PD) emerge as critical elements in averting equipment degradation and voltage instabilities. Acknowledging this pressing need, our discerning clients frequently seek insights into the practical applications of acoustic imaging technology to address PD challenges. In response to this demand, the CRYSOUND team takes pride in presenting a series of compelling case studies that highlight the precise utilization of acoustic imaging cameras across two pivotal domains: substations and power distribution systems.

Application Scene: Electricity Substations

1. Switchgear

The acoustic imaging camera efficiently detects partial discharge on switchgear cabinets via the inspection port. It aids personnel in confirming faults, minimizing downtime, and enhancing operational safety.

2. Wire

The acoustic imaging camera excels in detecting subtle partial discharge in 110kV cables, ensuring early detection of potential issues. Its advanced technology facilitates swift identification of weak points, empowering proactive maintenance.

3. High Voltage Room Insulator

Safety reigns supreme within high-voltage chambers. The handheld acoustic imaging camera provides a secure solution, enabling the precise detection of anomalies in insulators and equipment while maintaining safe distances. By leveraging this tool, risks to personnel are mitigated, and reliable power distribution is ensured.

4. Switch Insulator

Surface discharge incidents often occur on the porcelain pillars of switch cabinets. Acoustic imaging camera empower inspection teams to swiftly and precisely evaluate component performance, promptly identifying hazards.

Application Scene: Power Distribution System

1. Tower Insulator

The acoustic imaging camera remotely identifies abnormal discharges from distribution line insulators, facilitating early detection. Its precision ensures proactive mitigation of potential issues, enhancing grid reliability and safety.

2. Cable Distribution Box

Complex T-joints and busbar connections with high impedance are susceptible to discharge. Our acoustic imaging cameras simplify the identification of partial discharge, enabling precise localization and facilitating proactive maintenance to maximize grid stability and safety.

3. Drop Fuse

Defective fuses threaten system stability. CRYSOUND acoustic imaging camera promptly pinpoints partial discharge, facilitating prompt response.

4. Support Insulator

Continuous partial discharge in insulators erodes insulation properties. The height of support insulators hinders routine inspections. The CRYSOUND acoustic imaging camera enables safe, remote assessment, ensuring insulator integrity anduninterrupted power flow.

Partial discharge silently jeopardizes the safety and reliability of electrical systems. Rapid and precise identification of fault areas through acoustic imaging cameras is imperative for accident prevention and upholding the integrity of power systems. Leveraging the capabilities of acoustic imaging cameras guarantees the security and reliability of our electrical infrastructure.

For further information or to avail of our professional services, please do not hesitate to contact us. We are committed to providing effective solutions tailored to your needs!

System Devices

CRY2626G Drone-Mounted Acoustic Imaging Camera

The CRY2626G is the world’s first drone-mounted acoustic imaging camera for detection of pressurized system leaks and electrical partial discharge. The camera utilizes a microphone array with beamforming technology to pinpoint and acquire sound source distribution data and overlay it on a high-resolution video image.

The system features a 2-axis electric gimbal that allows pan and tilt control of the camera from the drone remote controller. This is beneficial for swiftly identifying potential gas leaks and partial discharge faults.

Featuring a robust and lightweight aluminum alloy body, the CRY2626G is designed to be durable under the most demanding environmental conditions. The included DJI SKYPORT allows for easy assembly and disassembly. Both photo and video modes are supported and data is stored on a large-capacity TF card for easy export of test results.

Get in touch

Are you seeking more information about CRYSOUND’s solutions or need a demo? Contact us via the form bleow and one of our sales or support engineers will connect with you.