Gas Leak Detection in Explosion-Proof Scenarios

A versatile gas leak detection tool designed for everyone

Explosion-proof site safety monitoring

The Current State of Leak Detection

In the past, leak detection demanded substantial resources in terms of manpower, materials, and time, leading to high operational costs. For instance, using soapy water to identify leaks in a chemical plant could take several weeks. Furthermore, for safety reasons, leak detection was often limited to production shutdown periods, adding to the overall complexity and expense.

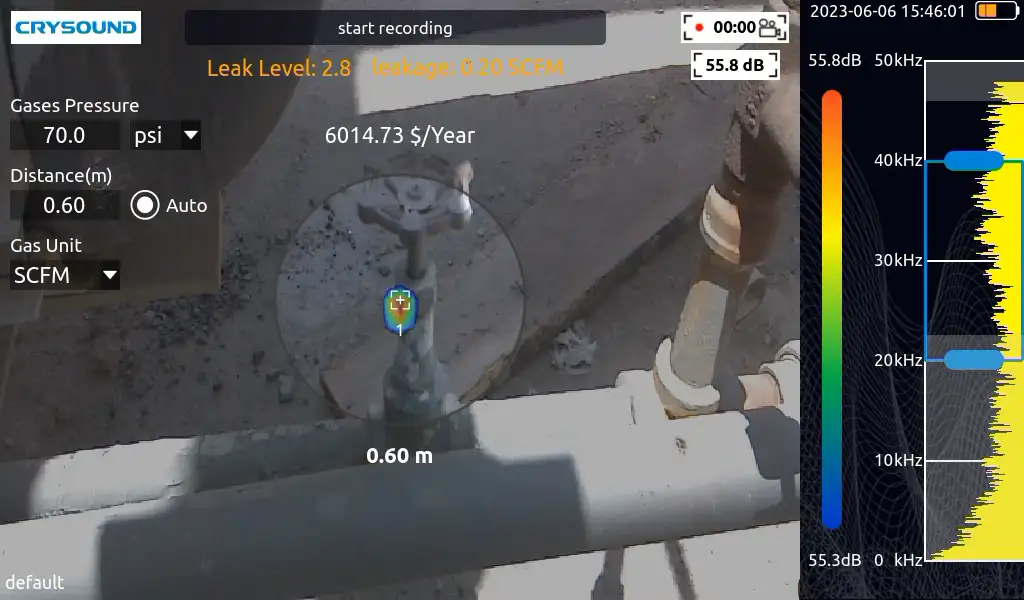

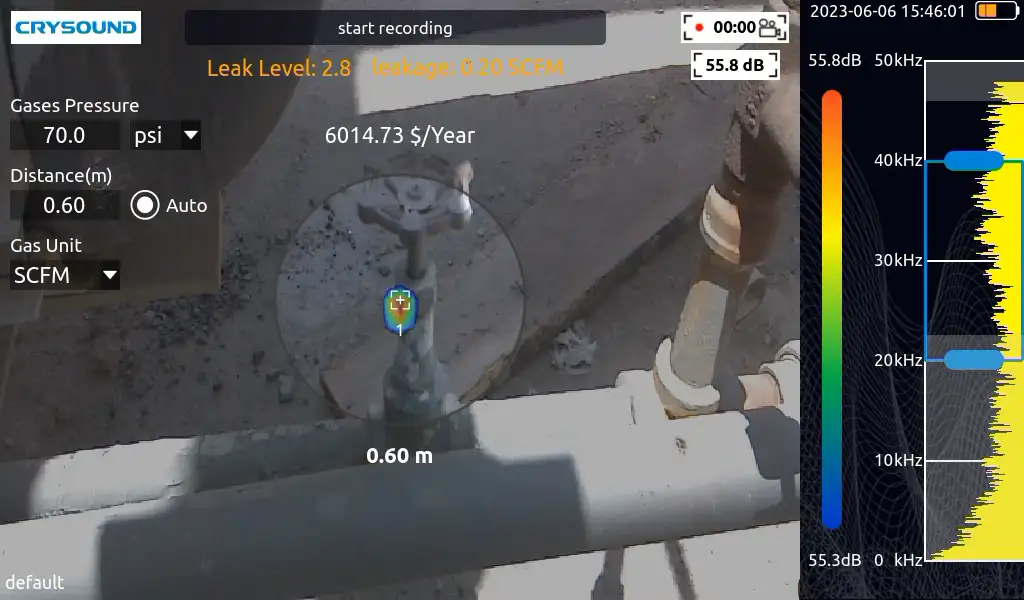

Improve detection efficiency by 10X

Real-time display of detection results improves detection efficiency and response capabilities.

A simple detection method

Aim the device at the area we need to evaluate and the detection results will be displayed.

Why Choose Acoustic Imaging Technology?

Unlike traditional leak detection methods like soapy water or gas concentration alarms, CRYSOUND utilizes advanced acoustic imaging technology to detect leaks. Our system identifies the distinct sound frequencies generated by gas leaks, enabling safe and efficient detection from a distance, regardless of the gas type.

Detects any type of gas

Regardless of the type of pressurized hazardous gas, users can detect any type of gas leak.

Long-distance detection

The device detects leaks from 0.3 ~ 120 m (1 ~ 393.7 ft), making climbing aids unnecessary.

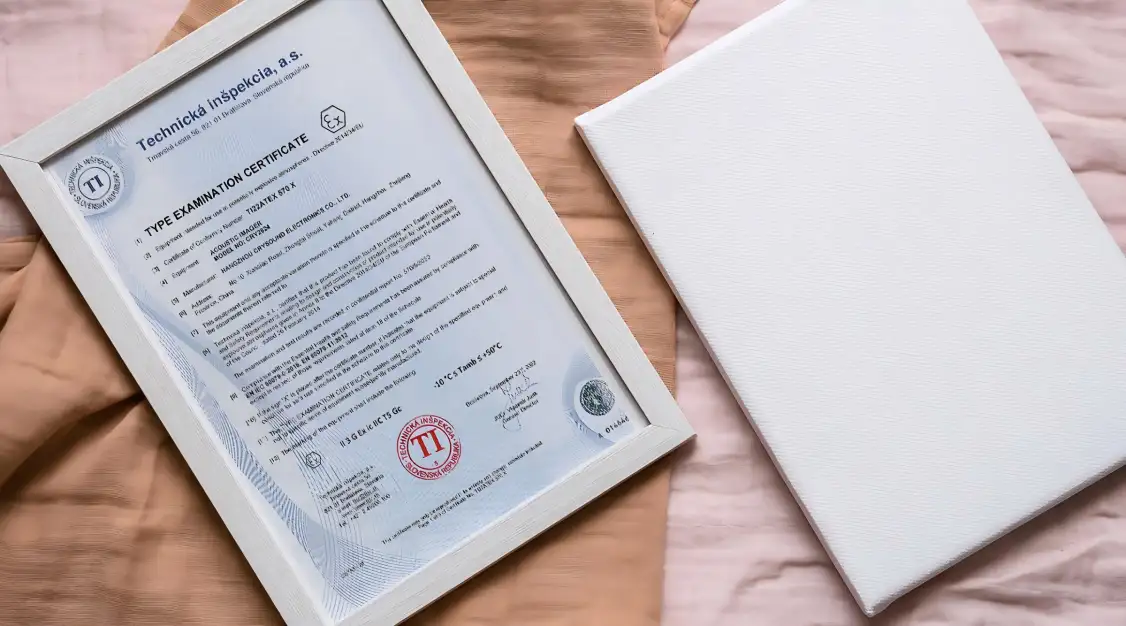

Suitable for Explosive Environments

The ATEX-certified CRYSOUND acoustic imaging camera has demonstrated exceptional effectiveness in detecting hazardous gases like hydrogen and acetylene, ensuring the safety and reliability of equipment in the field.

Explosion-proof requirements

The ATEX-certified device has been tested by a professional explosion-proof organization and obtained certification.

High accuracy

The device displays real-time detection results, quickly and accurately locating even the smallest gas leaks.

Save on Time & Cost

Chemical plants benefit greatly from acoustic imaging technology, which reduces the need for extensive materials, manpower, and time, ultimately driving down overall costs. This technology simplifies the detection of even small leaks of toxic or explosive gases, making it easier to align safety protocols with reliability objectives.

Better leak assessments

An acoustic imaging camera ensures all leak data is readily available, improving decision-making across various use cases.

Economic value analysis

Economic value analysis

Explore More Use Cases

CRYSOUND Acoustic Imaging Camera: The CRY8120 Series

For technicians in industrial facilities, using acoustic imaging cameras can boost safety and reduce costs. How? By quickly identifying leaks and partial discharge without “reading bubbles”. Here at CRYSOUND, we are raising the bar with our latest innovation—the CRY8120 Series Acoustic Imaging Cameras. This cutting-edge device not only transforms industrial inspections but also sets a new standard for performance and efficiency. Let’s check out the amazing capabilities, top-notch performance, and advanced features of the CRY8120, making it a must-have for industrial inspections.

Unparalleled Capabilities:

The CRY8120 acoustic imaging camera excels in various applications, including gas leak detection, electrical partial discharge identification, and mechanical deterioration monitoring. It outperforms traditional methods by providing results that are 10 times faster and more accurate. When it comes to gas leak detection, the CRY8120 swiftly pinpoints leak locations, estimates leakage volume, and potential economic losses in real-time. This capability reduces detection time, enabling faster repairs and reduced downtime. For electrical partial discharge detection, the camera displays PRPD charts in real-time, accurately identifying discharge types and aiding in informed decision-making for eff

icient maintenance and prevention of potential failures.

Best-in-Class Performance:

Equipped with 200 microphones, a 100 kHz bandwidth, and 10 times more computing power, the CRY8120 acoustic imaging camera offers unparalleled performance. Its ability to pinpoint even the smallest and most distant leaks with exceptional accuracy is a testament to its superior specifications. Unlike other acoustic camera solutions on the market, the CRY8120 can detect leaks up to 200m away. Despite these advanced features, the CRY8120 remains lightweight at just 1.4 kg, making it highly portable and suitable for deployment in various challenging industrial environments.

Enhanced Features for Convenience:

The CRY8120 acoustic imaging camera goes beyond its primary functionalities by offering a range of convenient features that enhance the user experience. Bluetooth and Wi-Fi connectivity enable wireless data transmission and quick report export, eliminating the need for cumbersome cables and saving valuable time.

Additionally, the integration of a thermal camera and contact sensors provides a comprehensive solution for diverse industrial scenarios, further extending the camera’s versatility and applicability.

Premium Display for Clear Visibility:

Featuring an impressive 8-inch display with a resolution of 1920 × 1200 pixels, the CRY8120 delivers a clear and detailed view of field conditions. The high-resolution display accurately renders leaks and other issues, magnifying every detail with its 13 million pixels and 6x digital zoom. Moreover, the display’s brightness of 600 nits ensures optimal visibility even in bright sunlight, making it suitable for outdoor inspections.

Long-Lasting Battery Life:

The CRY8120’s battery life is designed to accommodate extended inspection sessions. With a single battery, it provides up to 5 hours of continuous operation. For longer durations, an additional battery ensures uninterrupted use throughout the day. This extended battery life eliminates the need for frequent recharging, maximizing uptime and productivity.

Conclusion:

The CRY8120 acoustic imaging camera from CRYSOUND represents a groundbreaking advancement in the field of industrial inspections. Its unmatched capabilities, enhanced features, and superior performance make it an indispensable tool for inspection teams across industries. With the CRY8120, inspections become faster, more accurate, and more efficient, ensuring the safety and reliability of industrial equipment. Embrace the next generation of acoustic imaging technology and elevate your industrial inspection capabilities with the CRY8120 Series.

Fore more details, contact us by info@crysound.com

Quick and Safe Detection of Gas leaks in Hazardous Environments

In modern industrial production, gas leaks lead to resource wastage, and pose serious threats to employee safety and the environment. One of our clients in oil and gas industry reported that traditional leak detection methods can not accurately and efficiently locate leak points. Due to the hazardous environment, there are also potential safety issue for inspection personnel. At CRYSOUND, we understand the significance of this challenge and are here to provide valuable solution.

As we know, gas leaks often occur due to factors such as aging from prolonged use, corrosion, and improper installation, typically at equipment connection points like flanges and valves. Gas leaks should not be underestimated. Periodically inspection and maintenance can ensure the safety of production, enhance corporate image and market competitiveness.

.png)

For industrial production, quickly and accurately locating gas leaks is crucial. Providing assessments of leak volume and economic losses can serve as important references for corporate decision-making.

.png)

Our client successfully identified multiple leakage points at flanges and valves in the factory by actively using a handheld acoustic imaging camera. The handheld acoustic imaging camera provided assessments of leak volume and economic losses, allowing the client to selectively repair the leak points with larger leak volumes based on the evaluation data, thereby reducing losses in the factory.

.png)

For more information or to obtain professional services, please contact us. We are dedicated to provide effective solutions!

System Devices

CRY2624 128-Mic Industrial Acoustic Imaging Camera (ATEX)

The CRY2624 is a 128-mic industrial acoustic imaging camera and is designed for use in explosive environments within the chemical and energy industries. Featuring a robust aluminum alloy shell, this device is built to withstand complex and dynamic work conditions. It offers real-time sound image display, significantly improving the speed of detecting pressurized or vacuum leaks compared to other methods.

The CRY2624 is ATEX certified with a rating of II 3G Ex ic IIC T5 Gc, ensuring safe operation in potentially explosive atmospheres while adhering to stringent safety standards. The device supports camera and video modes, providing flexible on-site data recording. With an expandable large-capacity TF storage card, test results can be quickly exported and reported. This camera helps industrial facilities minimize losses from gas leaks, partial discharge, and other accidents, enhancing overall safety and operational efficiency.

Get in touch

Are you seeking more information about CRYSOUND’s solutions or need a demo? Contact us via the form bleow and one of our sales or support engineers will connect with you.