Automated Robotics for Precise PD Inspections

Fully automated testing process

The solution can reduce up to 80% of workload of human inspection

Intelligent transformation

Reduce 80% of the Workload

Currently, non-contact methods cannot accurately locate partial discharge in switchgear at distribution stations. However, the robotic acoustic imaging system offers dynamic monitoring of switchgear, allowing for timely pinpointing of partial discharge points. This solution can reduce up to 80% of the manual inspection workload.

Adopt a fully automated testing process

The robot automatically executes automated tasks following the set program.

Accurate identification and localization of fault problems

Non-contact acoustic imaging scheme can accurately locate fault points

Highly Intelligent Integration

Robot inspection routes are established along fixed lines at the station, enabling periodic monitoring of various equipment and data collection. This system meets the demands for low cost, full coverage, and enhanced visualization. It also supports 5G intelligent transformation, integrating multiple detection devices to provide multi-dimensional sensing of industrial factors such as sound, light, and electricity, while seamlessly interconnecting data and platforms.

Highly intelligent integration

The integration can be combined with other sensors to achieve multi-dimensional device status monitoring.

Data interoperability

Users can upload data to the platform through customized protocols.

Explore More Use Cases

Leveraging Acoustic Imaging for Effective Partial Discharge Detection

Within the intricate tapestry of electrical systems, where the paramount significance of ensuring power distribution safety and reliability cannot be overstated, the swift detection and mitigation of partial discharge (PD) emerge as critical elements in averting equipment degradation and voltage instabilities. Acknowledging this pressing need, our discerning clients frequently seek insights into the practical applications of acoustic imaging technology to address PD challenges. In response to this demand, the CRYSOUND team takes pride in presenting a series of compelling case studies that highlight the precise utilization of acoustic imaging cameras across two pivotal domains: substations and power distribution systems.

Application Scene: Electricity Substations

1. Switchgear

The acoustic imaging camera efficiently detects partial discharge on switchgear cabinets via the inspection port. It aids personnel in confirming faults, minimizing downtime, and enhancing operational safety.

2. Wire

The acoustic imaging camera excels in detecting subtle partial discharge in 110kV cables, ensuring early detection of potential issues. Its advanced technology facilitates swift identification of weak points, empowering proactive maintenance.

3. High Voltage Room Insulator

Safety reigns supreme within high-voltage chambers. The handheld acoustic imaging camera provides a secure solution, enabling the precise detection of anomalies in insulators and equipment while maintaining safe distances. By leveraging this tool, risks to personnel are mitigated, and reliable power distribution is ensured.

4. Switch Insulator

Surface discharge incidents often occur on the porcelain pillars of switch cabinets. Acoustic imaging camera empower inspection teams to swiftly and precisely evaluate component performance, promptly identifying hazards.

Application Scene: Power Distribution System

1. Tower Insulator

The acoustic imaging camera remotely identifies abnormal discharges from distribution line insulators, facilitating early detection. Its precision ensures proactive mitigation of potential issues, enhancing grid reliability and safety.

2. Cable Distribution Box

Complex T-joints and busbar connections with high impedance are susceptible to discharge. Our acoustic imaging cameras simplify the identification of partial discharge, enabling precise localization and facilitating proactive maintenance to maximize grid stability and safety.

3. Drop Fuse

Defective fuses threaten system stability. CRYSOUND acoustic imaging camera promptly pinpoints partial discharge, facilitating prompt response.

4. Support Insulator

Continuous partial discharge in insulators erodes insulation properties. The height of support insulators hinders routine inspections. The CRYSOUND acoustic imaging camera enables safe, remote assessment, ensuring insulator integrity anduninterrupted power flow.

Partial discharge silently jeopardizes the safety and reliability of electrical systems. Rapid and precise identification of fault areas through acoustic imaging cameras is imperative for accident prevention and upholding the integrity of power systems. Leveraging the capabilities of acoustic imaging cameras guarantees the security and reliability of our electrical infrastructure.

For further information or to avail of our professional services, please do not hesitate to contact us. We are committed to providing effective solutions tailored to your needs!

System Devices

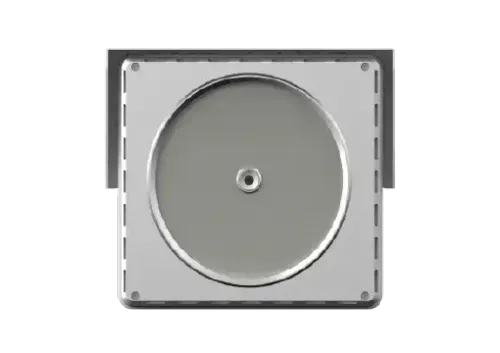

CRY2623M Fixed Acoustic Imaging Camera

The CRY2623M Fixed Acoustic Imaging Camera utilizes advanced microphone array beamforming technology to map sound source distribution and integrates with high-definition cameras for real-time video capture.

This system supports remote monitoring via local networks (LAN, WiFi) and wide area networks (WAN, ADSL, 4G, and private networks), facilitating industrial digital transformation. It enables real-time video monitoring and provides valuable insights into product quality and safety, allowing for the rapid detection of issues in compressors, pumps, pipes, cables, and more. With an IP66 protection rating, the CRY2623M is built to perform reliably in various harsh environments.

Get in touch

Are you seeking more information about CRYSOUND’s solutions or need a demo? Contact us via the form bleow and one of our sales or support engineers will connect with you.