Airtightness Testing of Composite Materials

Rapid leak detection of large composite material surfaces

Non-destructive leak testing of composite materials

Accelerate Airtightness Testing of Composites

Composite materials are widely utilized in the wind energy sector. Gas permeability testing of these materials is primarily conducted to assess their ability to prevent the penetration of gases or liquids, ensuring optimal product performance in various environmental conditions.

Existing technology is inefficient

The existing methods for detecting the gas tightness of composite materials require the establishment of complicated testing environments, and the testing efficiency is extremely low.

Inspections are unreliable

The existing gas tightness detection technologies mainly rely on the subjective judgment of inspectors, which can easily lead to errors, increasing the difficulty of testing.

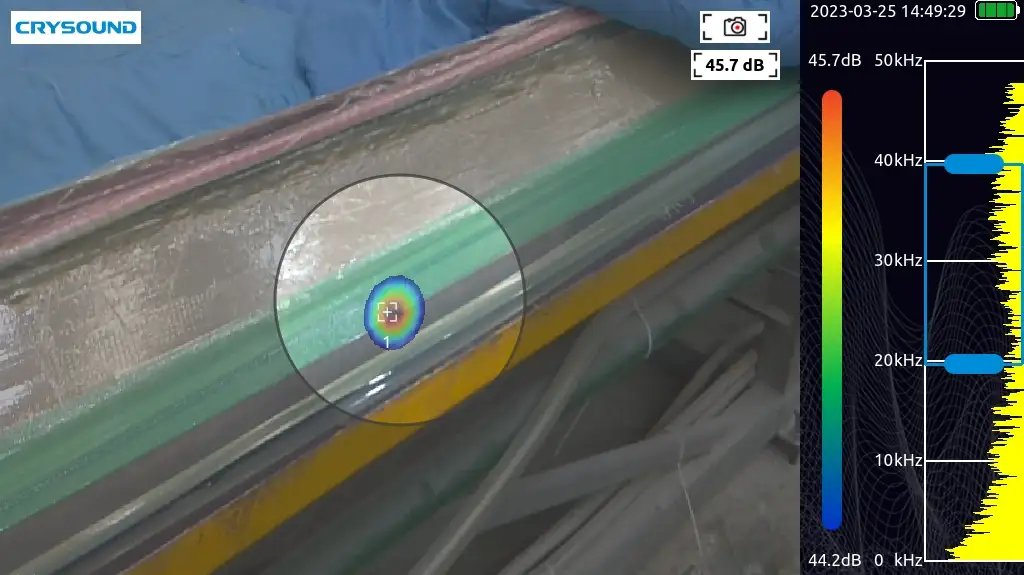

How Acoustic Imaging Detects Vacuum Leaks

Vacuum leaks produce ultrasonic waves, which are captured by the microphone array of the CRYSOUND acoustic imaging device. By processing these signals in real time, the device can quickly and accurately pinpoint the exact location of leaks. This technology allows anyone to perform comprehensive, reliable, and actionable leak detection with ease.

Background noise filtering

CRYSOUND acoustic imaging devices actively filter background noise while detecting leaks, even in noisy environments.

Easy-to-use for anyone

The devices are easy-to-use so anyone can find leaks reliably. Videos and pictures from the camera are easy to interpret.

Non-Destructive Testing

No-contact scanning and testing of mating sealing surfaces from a distance enable non-destructive air-tightness testing of vehicles and vessels.

Crates no damage

CRYSOUND devices do not cause any physical damage to the object being tested, making it suitable for negative pressure detection of blades.

Save time and costs

The detection process is simple and significantly reduces detection time and decreases errors.

High-Efficiency Detection

Acoustic imaging is a novel technology that provides a real-time visualization of leaks from a distance. With an acoustic imaging camera, anyone can pinpoint vacuum leaks 10x faster than traditional methods.

Real-time imaging

CRYSOUND devices provide real-time images and data, allowing engineers to quickly analyze and make decisions.

Results visualization

Results visualization

Explore More Use Cases

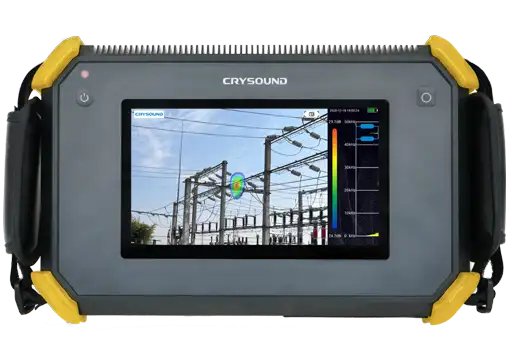

CRYSOUND Acoustic Imaging Camera: The CRY8120 Series

For technicians in industrial facilities, using acoustic imaging cameras can boost safety and reduce costs. How? By quickly identifying leaks and partial discharge without “reading bubbles”. Here at CRYSOUND, we are raising the bar with our latest innovation—the CRY8120 Series Acoustic Imaging Cameras. This cutting-edge device not only transforms industrial inspections but also sets a new standard for performance and efficiency. Let’s check out the amazing capabilities, top-notch performance, and advanced features of the CRY8120, making it a must-have for industrial inspections.

Unparalleled Capabilities:

The CRY8120 acoustic imaging camera excels in various applications, including gas leak detection, electrical partial discharge identification, and mechanical deterioration monitoring. It outperforms traditional methods by providing results that are 10 times faster and more accurate. When it comes to gas leak detection, the CRY8120 swiftly pinpoints leak locations, estimates leakage volume, and potential economic losses in real-time. This capability reduces detection time, enabling faster repairs and reduced downtime. For electrical partial discharge detection, the camera displays PRPD charts in real-time, accurately identifying discharge types and aiding in informed decision-making for eff

icient maintenance and prevention of potential failures.

Best-in-Class Performance:

Equipped with 200 microphones, a 100 kHz bandwidth, and 10 times more computing power, the CRY8120 acoustic imaging camera offers unparalleled performance. Its ability to pinpoint even the smallest and most distant leaks with exceptional accuracy is a testament to its superior specifications. Unlike other acoustic camera solutions on the market, the CRY8120 can detect leaks up to 200m away. Despite these advanced features, the CRY8120 remains lightweight at just 1.4 kg, making it highly portable and suitable for deployment in various challenging industrial environments.

Enhanced Features for Convenience:

The CRY8120 acoustic imaging camera goes beyond its primary functionalities by offering a range of convenient features that enhance the user experience. Bluetooth and Wi-Fi connectivity enable wireless data transmission and quick report export, eliminating the need for cumbersome cables and saving valuable time.

Additionally, the integration of a thermal camera and contact sensors provides a comprehensive solution for diverse industrial scenarios, further extending the camera’s versatility and applicability.

Premium Display for Clear Visibility:

Featuring an impressive 8-inch display with a resolution of 1920 × 1200 pixels, the CRY8120 delivers a clear and detailed view of field conditions. The high-resolution display accurately renders leaks and other issues, magnifying every detail with its 13 million pixels and 6x digital zoom. Moreover, the display’s brightness of 600 nits ensures optimal visibility even in bright sunlight, making it suitable for outdoor inspections.

Long-Lasting Battery Life:

The CRY8120’s battery life is designed to accommodate extended inspection sessions. With a single battery, it provides up to 5 hours of continuous operation. For longer durations, an additional battery ensures uninterrupted use throughout the day. This extended battery life eliminates the need for frequent recharging, maximizing uptime and productivity.

Conclusion:

The CRY8120 acoustic imaging camera from CRYSOUND represents a groundbreaking advancement in the field of industrial inspections. Its unmatched capabilities, enhanced features, and superior performance make it an indispensable tool for inspection teams across industries. With the CRY8120, inspections become faster, more accurate, and more efficient, ensuring the safety and reliability of industrial equipment. Embrace the next generation of acoustic imaging technology and elevate your industrial inspection capabilities with the CRY8120 Series.

Fore more details, contact us by info@crysound.com

System Devices

CRY2620 64-Mic Industrial Acoustic Imaging Camera

The CRY2620 Industrial Acoustic Imaging Camera is designed for ease of use and quick operation. Its robust aluminum alloy shell ensures durability, making it adaptable to complex and changing work environments. The device provides a real-time sound image display, significantly accelerating the detection of pressurized or vacuum leaks compared to traditional methods.

The CRY2620 simplifies testing with just two adjustable parameters: test frequency range and dynamic range, covering most testing needs.

It offers multiple modes, including camera and video modes, along with flexible on-site data recording. The large-capacity TF storage card is expandable, allowing for quick export and reporting of test results.

This device helps enterprises minimize losses from gas leaks and other accidents, enhancing overall operational safety.

CRY2623 128-Mic Industrial Acoustic Imaging Camera

The CRY2623 is a 128-mic industrial acoustic imaging camera that is user-friendly and requires minimal training. Its durable aluminum alloy shell is built to withstand complex and variable working conditions. The device offers real-time acoustic imaging, significantly accelerating the detection of pressurized or vacuum leaks compared to traditional methods. It supports both photo and video modes for flexible on-site data recording. With an expandable large-capacity TF storage card, test results can be quickly exported and reported. The CRY2623 helps enterprises reduce safety risks and minimize economic losses associated with gas leaks, partial discharges, and other malfunctions.

CRY8124 Advanced Acoustic Imaging Camera

Introducing CRYSOUND’s cutting-edge acoustic imaging camera, revolutionizing industrial inspections with advanced capabilities. The CRY8124 acoustic imaging camera excels at pinpointing leaks, identifying electrical partial discharge, and detecting mechanical deterioration. Setting a new standard for sensitivity and efficiency, the CRY8124 boasts 200 microphones (the most in the industry). The device detects smaller leaks and partial discharges from greater distance than any other handheld acoustic imaging camera on the market.

The CRY8124 reporting software allows offline analysis, editing, and report generation, simplifying regular maintenance routines.

Elevate the effectiveness of your industrial inspections with CRYSOUND’s acoustic cameras.

Get in touch

Are you seeking more information about CRYSOUND’s solutions or need a demo? Contact us via the form bleow and one of our sales or support engineers will connect with you.