Robotic Integrated Gas Leak Detection

Robot-intelligent gas leak inspection

Unmanned inspection of hazardous areas

Multi-Technological Integration

Integrating robotics with audio-visual technology significantly boosts efficiency and accuracy in inspections. Robots can autonomously navigate complex environments, capture detailed data, monitor in real-time, detect anomalies efficiently, and generate comprehensive reports. This integration makes inspections safer and more effective across diverse industries.

Improve inspection efficiency

By employing robotic inspection, the number and frequency of inspection personnel can be reduced, requiring only a small team of technical staff to oversee and maintain the robots.

Visual Monitoring

The integration of acoustic imaging and visible light technology enables the visualization of abnormal sound sources on-site.

Intelligent Inspection

Intelligent inspection utilizes advanced technologies such as artificial intelligence, robotics, acoustic imaging, and data analytics to automate monitoring processes. It improves efficiency, accuracy, and safety by enabling real-time data collection, anomaly detection, and predictive maintenance across various industries, ensuring optimal performance and timely interventions.

Customized inspections

Customized robotic inspection cycles, routes, and points enable comprehensive coverage monitoring.

Reduce the false/positive rate

Advanced sensors and algorithms enable more accurate data analysis, reduce human errors, and achieve more effective monitoring and maintenance.

Monitoring & Early Warning System

The monitoring and early warning system detects anomalies and potential threats through real-time data analysis. It provides timely alerts to enhance safety and operational efficiency across various sectors, including security, transportation, and industrial processes.

Real-time data analysis

Through real-time data analysis, you can gain immediate insights and make timely decisions, thereby improving efficiency and responsiveness.

Real-time alerts

Real-time alerts provide immediate notifications about critical events, enabling prompt responses and proactive measures to mitigate risks and enhance safety.

Data Traceability

Data traceability is the ability to track, verify, view, and analyze historical data. It ensures transparency and compliance, allowing organizations to trace information based on accurate historical data and make informed decisions.

Comprehensive data storage

It ensures all information is securely maintained, facilitating easy access, enhanced analysis, and improved decision-making across various applications.

Alarm localization

Alarm localization

Safety Inspection

With advanced automation technology to enhance the safety of inspection operations, these robots systematically monitor the environment and potential hazards. This minimizes human risks while boosting inspection efficiency. Ultimately, they play a vital role in ensuring site safety.

Unmanned Monitoring

Achieving on-site inspections and ensuring safety through robotic technology, without the need for human intervention.

Hazardous Area Monitoring

Robotic inspections can conduct tasks in flammable, explosive, and toxic hazardous areas, reducing the risks associated with personnel inspections.

Explore More Use Cases

Quick and Safe Detection of Gas leaks in Hazardous Environments

In modern industrial production, gas leaks lead to resource wastage, and pose serious threats to employee safety and the environment. One of our clients in oil and gas industry reported that traditional leak detection methods can not accurately and efficiently locate leak points. Due to the hazardous environment, there are also potential safety issue for inspection personnel. At CRYSOUND, we understand the significance of this challenge and are here to provide valuable solution.

As we know, gas leaks often occur due to factors such as aging from prolonged use, corrosion, and improper installation, typically at equipment connection points like flanges and valves. Gas leaks should not be underestimated. Periodically inspection and maintenance can ensure the safety of production, enhance corporate image and market competitiveness.

.png)

For industrial production, quickly and accurately locating gas leaks is crucial. Providing assessments of leak volume and economic losses can serve as important references for corporate decision-making.

.png)

Our client successfully identified multiple leakage points at flanges and valves in the factory by actively using a handheld acoustic imaging camera. The handheld acoustic imaging camera provided assessments of leak volume and economic losses, allowing the client to selectively repair the leak points with larger leak volumes based on the evaluation data, thereby reducing losses in the factory.

.png)

For more information or to obtain professional services, please contact us. We are dedicated to provide effective solutions!

System Devices

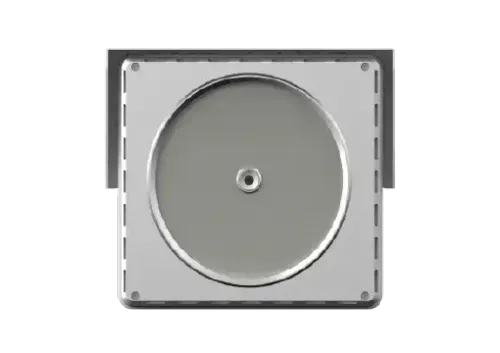

CRY2623M Fixed Acoustic Imaging Camera

The CRY2623M Fixed Acoustic Imaging Camera utilizes advanced microphone array beamforming technology to map sound source distribution and integrates with high-definition cameras for real-time video capture.

This system supports remote monitoring via local networks (LAN, WiFi) and wide area networks (WAN, ADSL, 4G, and private networks), facilitating industrial digital transformation. It enables real-time video monitoring and provides valuable insights into product quality and safety, allowing for the rapid detection of issues in compressors, pumps, pipes, cables, and more. With an IP66 protection rating, the CRY2623M is built to perform reliably in various harsh environments.

Get in touch

Are you seeking more information about CRYSOUND’s solutions or need a demo? Contact us via the form bleow and one of our sales or support engineers will connect with you.