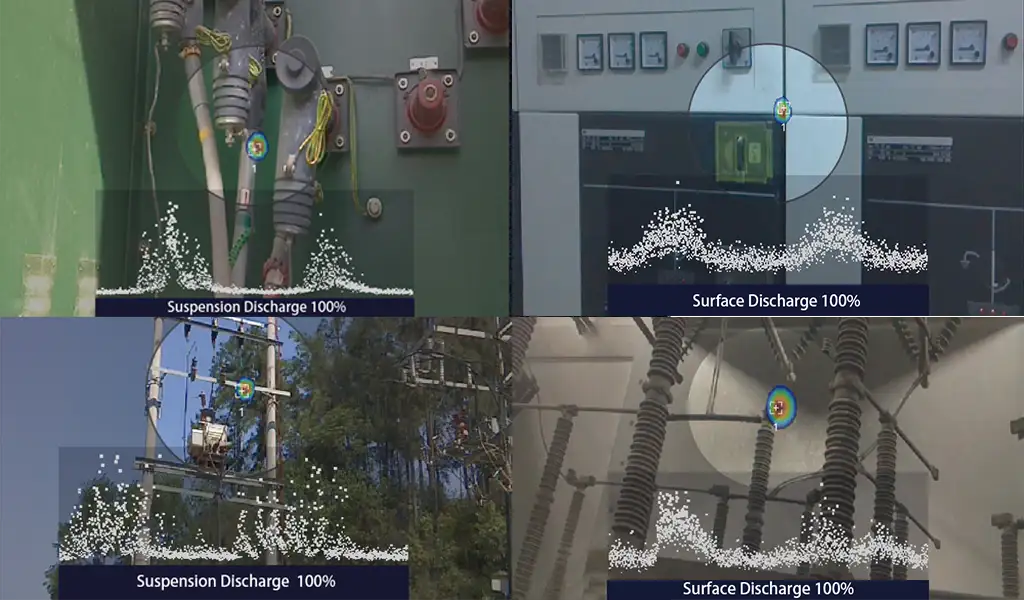

PD Detection in Common Scenarios

Dedicated models for partial discharge detection

Handheld, fixed or even drone-mounted options

Identify PD at a Glance

The Acoustic Imaging Camera converts the ultrasound emitted by a partial discharge into an acoustic field localization and superimposes it on the visible light picture captured in real time. With its ability to cover long distances and a wide field of view, the Acoustic Imaging Camera can quickly identify partial discharges

Locate PD in real-time

As the camera scans the area, it instantly visualizes the location of PD on the screen.

Works for all PD types

Inspection teams can quickly and accurately assess the operation of switch cabinet components using acoustic imaging camera, thereby identifying safety hazards in a timely manner.

Safety operation requirements applicable to various scenarios

Acoustic imaging technology, as a non-contact detection means, can ensure the life safety of the staff in the working environment with dense high-voltage facilities. In different power system scenarios, the handheld acoustic imager can accurately analyze partial discharge defects in many different types of key equipment.

Electricity Substations

In substation scenarios, the Acoustic Imaging Camera can efficiently monitor the operation of switchgear, cables, high-voltage chamber porcelain vases, switch insulators, and other equipment while also investigating potential safety hazards.

Distribution system

Distribution lines transport energy to any location that requires electricity, resulting in long and complex distribution lines. The Acoustic Imaging Camera provide ultra-long-distance detection capabilities, allowing inspectors to readily detect numerous equipment on towers from a comfortable distance, ensuring the power system's safe operation.

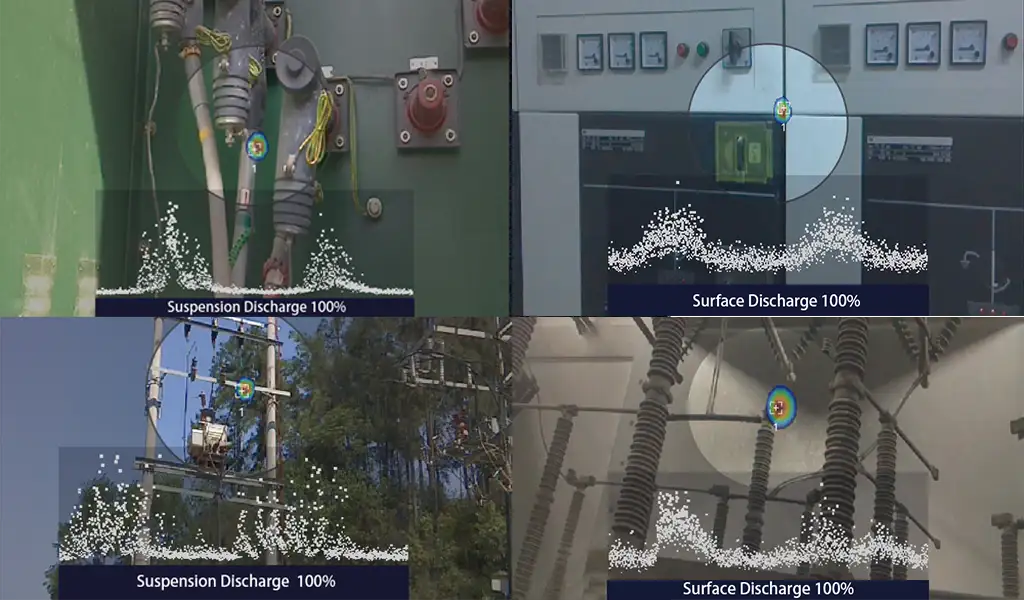

Listening + PRPD mapping to get more accurate localized discharge type determination

The natural environment has many sound sources in the ultrasonic frequency band, and this situation is especially common in power plants. In order to distinguish the interfering sound sources more effectively, we apply the PRPD map recognition function, which helps us to distinguish the discharge types in the complex environment. Also, our equipment is equipped with an ultrasonic listening function, which can convert audio models in the ultrasonic frequency band into audible sound through a series of processing.

More accurate judgment

The method of listening and mapping can improve the accuracy of the fault identification.

Eliminate the interference of irrelevant sound sources

PRPD mapping can clearly determine the type of sound source.

Minimal Training Requirements

Other PD detection solutions require specialized training to interpret images, distinguish between true PD and false positives, and navigate complex industrial environments. With sophisticated acoustic camera technology, users can quickly learn how to operate the device, saving time and improving work efficiency.

Intuitive display

The screen of the acoustic camera presents vivid images with a touchscreen interface.

No experts needed

No experts needed

Measuring the extent of PD

Acoustic imaging cameras use advanced algorithms to quantify partial discharge by analyzing factors such as sound pressure levels, partial discharge types, and other characteristics. By considering variables such as component value, risk of outage, and more, acoustic imaging cameras can help customers make more informed decisions.

See the extent of PD

Based on the measured dB SPL value, the acoustic camera calculates the leak rate and economic loss of each leak

Streamline the reporting process

Using reporting tools, data can be shared between teams to prioritize repairs and optimize resource allocation

Explore More Use Cases

How to Address Partial Discharge in Generators

Partial discharge is a phenomenon that cannot be completely eliminated from high-voltage motors and generators. However, it is crucial to closely monitor and address partial discharge, as it can impact the performance of insulating materials.

In the power industry, inspectors rely on observing the working status and performance of motors by studying the trend of partial discharge intensity in the generator.

If the intensity of partial discharge in the generator shows an upward trend, it indicates a potential issue within the generator. At this point, it becomes necessary to analyze the underlying cause of this phenomenon and conduct a thorough examination of the motor’s functionality.

.jpeg)

By taking proactive measures to address partial discharge, our clients can ensure the reliability and longevity of their generator systems. CRYSOUND’s Acoustic Imager has proven to be an effective tool in detecting suspension discharge and surface discharge, assisting our clients in identifying and resolving potential problems early on.

.jpeg)

The CRYSOUND Acoustic Imager enables inspectors to analyze the intensity of partial discharge in the generator and closely monitor the functionality of the motors, thereby ensuring the safety of the environment.

.jpeg)

If you are facing similar challenges or have any questions related to partial discharge in generators, feel free to reach out to our team at CRYSOUND. We are here to provide expert guidance and support every step of the way. Contact us.

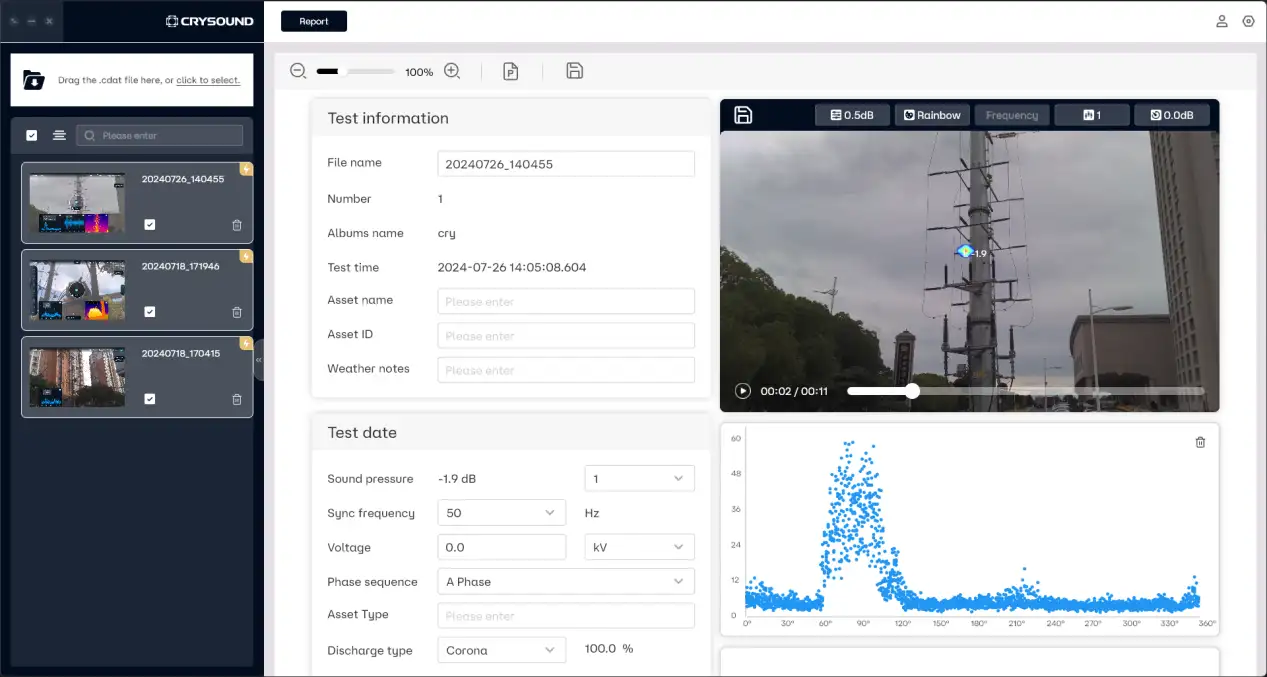

Leveraging Acoustic Imaging for Effective Partial Discharge Detection

Within the intricate tapestry of electrical systems, where the paramount significance of ensuring power distribution safety and reliability cannot be overstated, the swift detection and mitigation of partial discharge (PD) emerge as critical elements in averting equipment degradation and voltage instabilities. Acknowledging this pressing need, our discerning clients frequently seek insights into the practical applications of acoustic imaging technology to address PD challenges. In response to this demand, the CRYSOUND team takes pride in presenting a series of compelling case studies that highlight the precise utilization of acoustic imaging cameras across two pivotal domains: substations and power distribution systems.

Application Scene: Electricity Substations

1. Switchgear

The acoustic imaging camera efficiently detects partial discharge on switchgear cabinets via the inspection port. It aids personnel in confirming faults, minimizing downtime, and enhancing operational safety.

2. Wire

The acoustic imaging camera excels in detecting subtle partial discharge in 110kV cables, ensuring early detection of potential issues. Its advanced technology facilitates swift identification of weak points, empowering proactive maintenance.

3. High Voltage Room Insulator

Safety reigns supreme within high-voltage chambers. The handheld acoustic imaging camera provides a secure solution, enabling the precise detection of anomalies in insulators and equipment while maintaining safe distances. By leveraging this tool, risks to personnel are mitigated, and reliable power distribution is ensured.

4. Switch Insulator

Surface discharge incidents often occur on the porcelain pillars of switch cabinets. Acoustic imaging camera empower inspection teams to swiftly and precisely evaluate component performance, promptly identifying hazards.

Application Scene: Power Distribution System

1. Tower Insulator

The acoustic imaging camera remotely identifies abnormal discharges from distribution line insulators, facilitating early detection. Its precision ensures proactive mitigation of potential issues, enhancing grid reliability and safety.

2. Cable Distribution Box

Complex T-joints and busbar connections with high impedance are susceptible to discharge. Our acoustic imaging cameras simplify the identification of partial discharge, enabling precise localization and facilitating proactive maintenance to maximize grid stability and safety.

3. Drop Fuse

Defective fuses threaten system stability. CRYSOUND acoustic imaging camera promptly pinpoints partial discharge, facilitating prompt response.

4. Support Insulator

Continuous partial discharge in insulators erodes insulation properties. The height of support insulators hinders routine inspections. The CRYSOUND acoustic imaging camera enables safe, remote assessment, ensuring insulator integrity anduninterrupted power flow.

Partial discharge silently jeopardizes the safety and reliability of electrical systems. Rapid and precise identification of fault areas through acoustic imaging cameras is imperative for accident prevention and upholding the integrity of power systems. Leveraging the capabilities of acoustic imaging cameras guarantees the security and reliability of our electrical infrastructure.

For further information or to avail of our professional services, please do not hesitate to contact us. We are committed to providing effective solutions tailored to your needs!

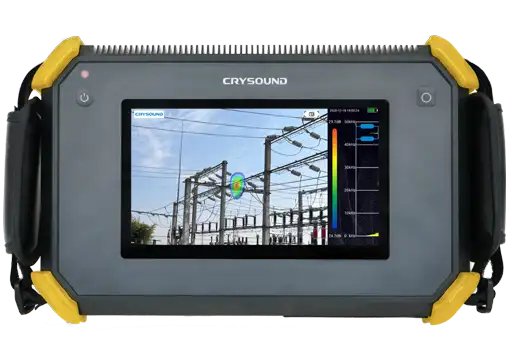

System Devices

CRY8124 Advanced Acoustic Imaging Camera

Introducing CRYSOUND’s cutting-edge acoustic imaging camera, revolutionizing industrial inspections with advanced capabilities. The CRY8124 acoustic imaging camera excels at pinpointing leaks, identifying electrical partial discharge, and detecting mechanical deterioration. Setting a new standard for sensitivity and efficiency, the CRY8124 boasts 200 microphones (the most in the industry). The device detects smaller leaks and partial discharges from greater distance than any other handheld acoustic imaging camera on the market.

The CRY8124 reporting software allows offline analysis, editing, and report generation, simplifying regular maintenance routines.

Elevate the effectiveness of your industrial inspections with CRYSOUND’s acoustic cameras.

CRY2623 128-Mic Industrial Acoustic Imaging Camera

The CRY2623 is a 128-mic industrial acoustic imaging camera that is user-friendly and requires minimal training. Its durable aluminum alloy shell is built to withstand complex and variable working conditions. The device offers real-time acoustic imaging, significantly accelerating the detection of pressurized or vacuum leaks compared to traditional methods. It supports both photo and video modes for flexible on-site data recording. With an expandable large-capacity TF storage card, test results can be quickly exported and reported. The CRY2623 helps enterprises reduce safety risks and minimize economic losses associated with gas leaks, partial discharges, and other malfunctions.

Get in touch

Are you seeking more information about CRYSOUND’s solutions or need a demo? Contact us via the form bleow and one of our sales or support engineers will connect with you.