7/24 Online Monitoring Gas Leak

24/7 real-time visual monitoring

Fixed, gimbal, mobile installation

Real-time alarm triggering

Quickly Respond to Asset Issues

Fixed acoustic camera systems provide continuous monitoring, enabling swift responses to asset issues. By detecting anomalies in real-time, these systems alert teams to potential problems before they escalate. This proactive approach minimizes downtime and prevents costly failures, ensuring optimal operational efficiency.

Prevent Severe Equipment Damage & Accidents

By continuously monitoring and analyzing sound patterns, these systems detect early signs of potential failures or abnormal conditions. This method allows for timely maintenance and intervention, reducing the risk of catastrophic equipment breakdowns and safety incidents. With real-time alerts and precise fault localization, these systems help ensure that issues are addressed before they escalate, protecting both equipment and personnel from significant harm and costly disruptions.

Reduce Maintenance Costs

Fixed acoustic cameras continuously monitor sound patterns, identifying issues with pinpoint precision. By detecting faults early and accurately, maintenance can be performed precisely where needed, avoiding unnecessary inspections and repairs. This targeted approach minimizes downtime, extends equipment life, and reduces labor and material costs, ultimately leading to more efficient and cost-effective maintenance operations.

Identify Gas Leaks in Real-Time

These systems provide continuous real-time gas leak monitoring, detecting even the smallest escapes with precision. Utilizing advanced acoustic technology, fixed acoustic cameras identify leaks regardless of the gas type. By promptly detecting leaks, they prevent potential hazards, reduce gas loss, and enhance safety. Whether it’s methane, hydrogen, or any industrial gas, these systems ensure no leak goes unnoticed, delivering peace of mind and operational efficiency.

Increase Personnel Safety

Fixed acoustic camera systems are designed to keep personnel safe while inspecting hazardous areas. By remotely detecting and locating gas leaks or other anomalies, acoustic imaging devices eliminate the need for workers to enter dangerous environments. This not only enhances safety but also ensures continuous monitoring and quick response to potential issues.

Explore More Use Cases

Quick and Safe Detection of Gas leaks in Hazardous Environments

In modern industrial production, gas leaks lead to resource wastage, and pose serious threats to employee safety and the environment. One of our clients in oil and gas industry reported that traditional leak detection methods can not accurately and efficiently locate leak points. Due to the hazardous environment, there are also potential safety issue for inspection personnel. At CRYSOUND, we understand the significance of this challenge and are here to provide valuable solution.

As we know, gas leaks often occur due to factors such as aging from prolonged use, corrosion, and improper installation, typically at equipment connection points like flanges and valves. Gas leaks should not be underestimated. Periodically inspection and maintenance can ensure the safety of production, enhance corporate image and market competitiveness.

.png)

For industrial production, quickly and accurately locating gas leaks is crucial. Providing assessments of leak volume and economic losses can serve as important references for corporate decision-making.

.png)

Our client successfully identified multiple leakage points at flanges and valves in the factory by actively using a handheld acoustic imaging camera. The handheld acoustic imaging camera provided assessments of leak volume and economic losses, allowing the client to selectively repair the leak points with larger leak volumes based on the evaluation data, thereby reducing losses in the factory.

.png)

For more information or to obtain professional services, please contact us. We are dedicated to provide effective solutions!

System Devices

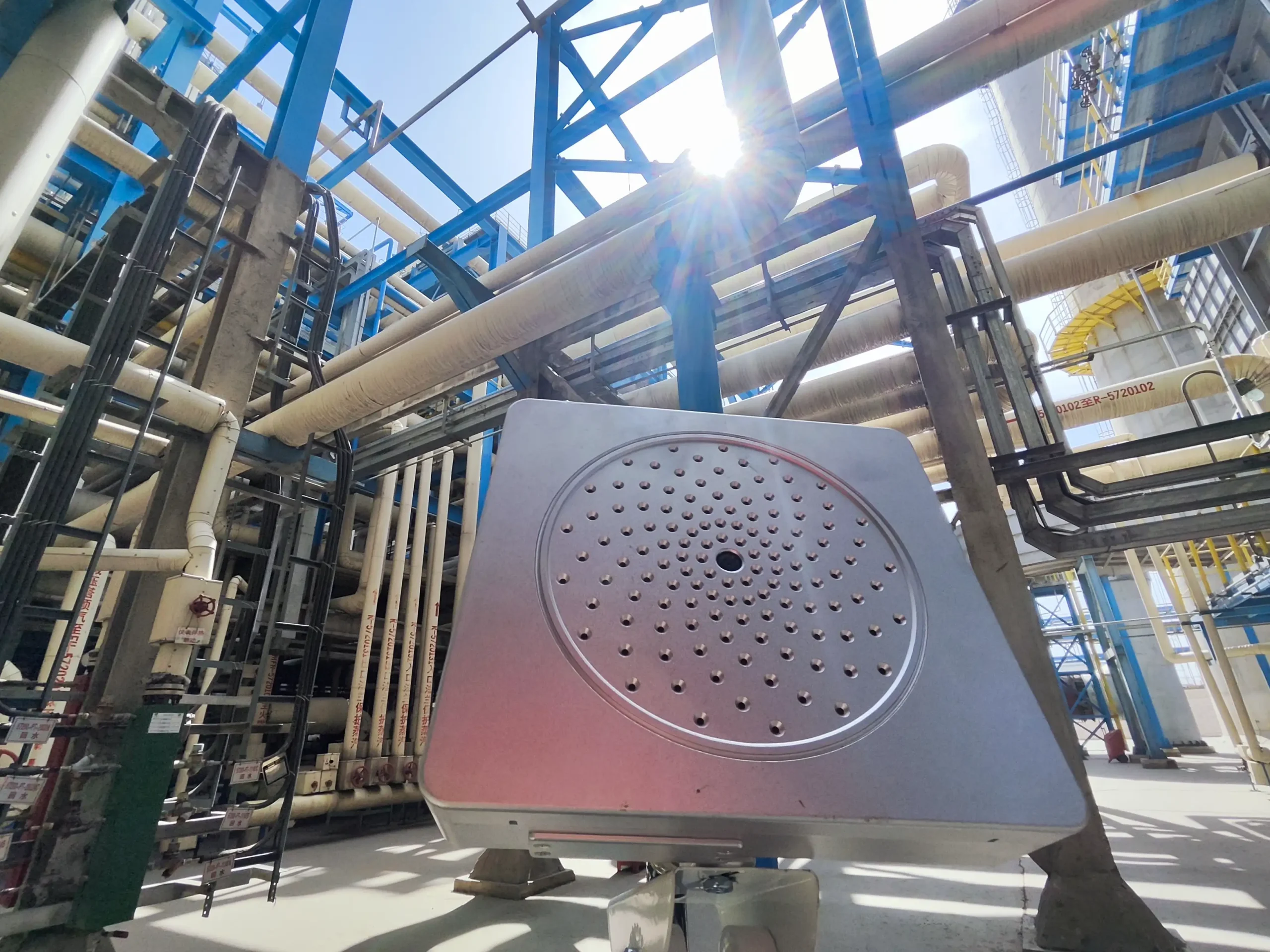

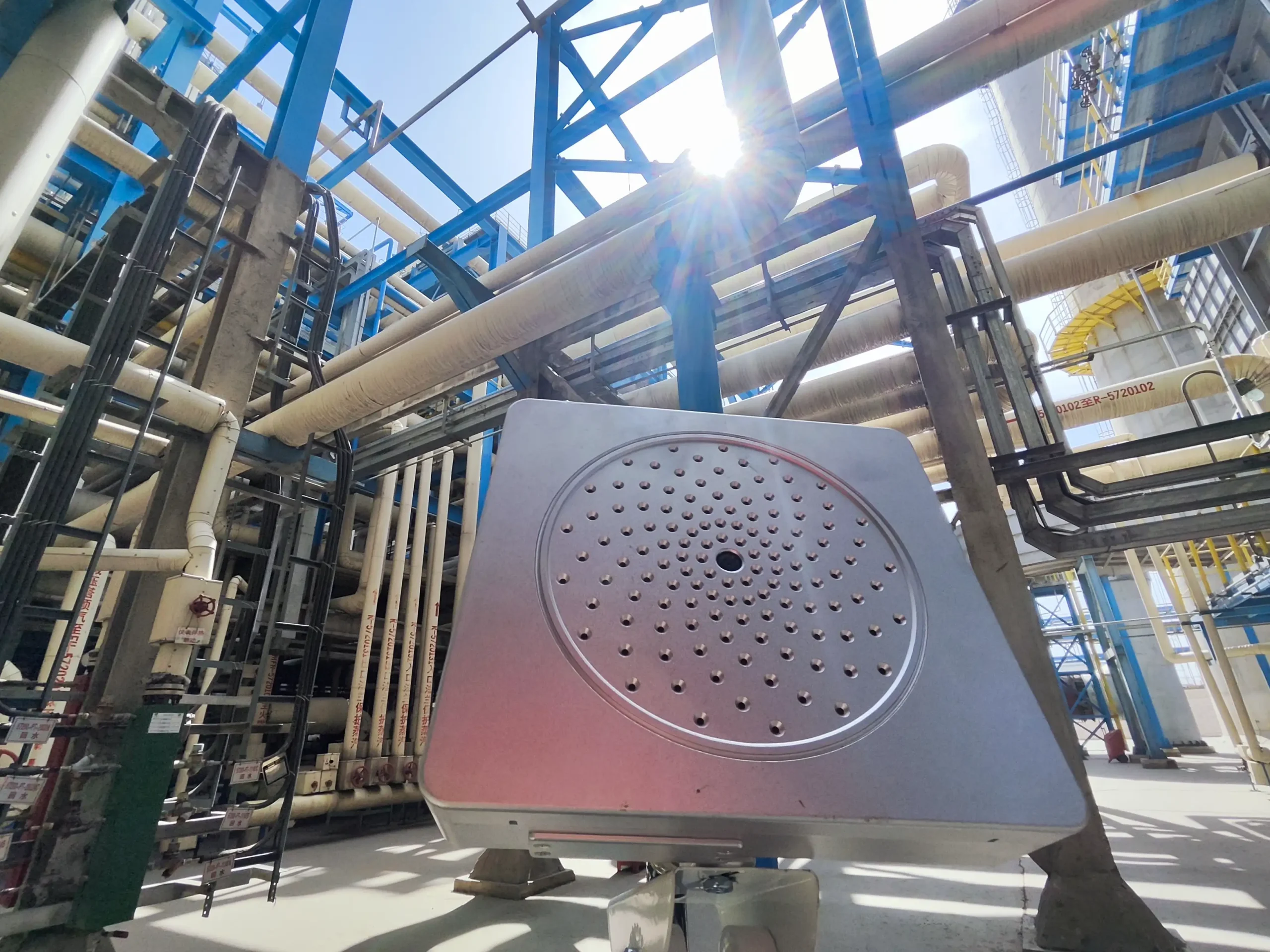

CRY2623M Fixed Acoustic Imaging Camera

The CRY2623M Fixed Acoustic Imaging Camera utilizes advanced microphone array beamforming technology to map sound source distribution and integrates with high-definition cameras for real-time video capture.

This system supports remote monitoring via local networks (LAN, WiFi) and wide area networks (WAN, ADSL, 4G, and private networks), facilitating industrial digital transformation. It enables real-time video monitoring and provides valuable insights into product quality and safety, allowing for the rapid detection of issues in compressors, pumps, pipes, cables, and more. With an IP66 protection rating, the CRY2623M is built to perform reliably in various harsh environments.

Get in touch

Are you seeking more information about CRYSOUND’s solutions or need a demo? Contact us via the form bleow and one of our sales or support engineers will connect with you.